Welcome to “The Gear Behind the Game,” where we explore how uniforms and branded sportswear go from concept to kickoff. In this post, we’ll focus on one of the most important topics for any emerging teamwear brand: custom apparel production. Whether you’re an aspiring entrepreneur, a team organizer, or simply curious about how to launch your own line, understanding this process is crucial.

According to recent market reports, the global custom apparel market is expected to grow by USD 2.45 billion from 2025 to 2029, reflecting an 8.4% CAGR (prnewswire.com). This growth reveals a promising opportunity for small to medium-sized brands eager to stand out in a busy marketplace.

Below, you’ll learn the five essential steps for a successful start in custom apparel production, along with practical tips and insights to guide you.

Step 1: Market Research for Custom Apparel Production

Before you dive into production, take time to research who will wear your apparel and why they want it. Market research is a foundational aspect of custom apparel production because every brand must understand its audience before making any major decisions.

For instance, if you’re focusing on youth sports teams, you’ll want to explore what design features excite younger athletes—like bold graphics or advanced performance fabrics. Knowing facts like the Asia-Pacific region being the fastest-growing market for sports apparel (worldmetrics.org) can also help you decide where to source materials or even which regions to target in online ads.

One way to begin market research is by comparing competitor products and pricing. Platforms such as Custom Ink and Wooter can serve as starting points to see what successful teamwear companies are doing.

You should also keep trends in mind—sustainable sportswear, bold graphics, personalization, and advanced performance fabrics are all on the rise. It’s here that you’ll start to shape your own brand identity and positioning, which will be crucial as you move forward with custom apparel production.

Step 2: Concept and Design in Custom Apparel Production

Once you know your target market, it’s time to focus on the creative side of custom apparel production. Concept and design involve everything from sketching initial ideas to finalizing graphics and color schemes.

Eco-friendly materials are also gaining popularity, so consider whether you’ll incorporate organic cotton or recycled polyester to appeal to environmentally conscious customers. In 2023 alone, more than 100 million T-shirts were manufactured using organic cotton (astuteanalytica.com), highlighting the growing importance of sustainable design choices.

During this step, tools like Adobe Illustrator or CorelDRAW can help you bring your vision to life. Pattern drafting software such as Valentina can be essential if you plan on a “cut and sew” approach, where each garment is custom-tailored to specific measurements. If you’re leaning toward sublimation printing—widely used for vivid, all-over designs—make sure to consider fabrics that accommodate that process.

Don’t overlook moisture-wicking fabrics for sports uniforms, as athletes want comfort and high performance. This stage will define how your final products look and feel, so gather feedback from mentors, fellow designers, or even potential customers whenever possible.

Step 3: Material Sourcing and Partnerships in Custom Apparel Production

A major component of custom apparel production is choosing quality fabrics and reliable factories. You’ll need to find suppliers that meet your pricing, material, and ethical standards. If you’re a small company looking for lower minimum order quantities (MOQs), platforms like Printful, Teespring, or Zazzle may help you get started without demanding large upfront purchases.

Alternatively, if you aim to produce large volumes, you’ll want to partner with more traditional cut-and-sew facilities or direct printing houses. Partnerships with factories that are flexible and transparent in communication can be a game-changer.

When deciding who to work with, consider lead times, shipping costs, and any certifications they offer (e.g., for organic or recycled content). Keep in mind that sustainable and performance fabrics are in demand. The global sustainable sports apparel market is forecasted to grow by 10.4% annually (worldmetrics.org), so partnering with a supplier that can provide eco-friendly options may give you a competitive edge.

Additionally, familiarizing yourself with moisture-wicking fabric technology can enhance the appeal of your uniforms for serious athletes. Lastly, remember to request samples from potential suppliers. Testing fabric quality and the durability of prints will prevent costly mistakes down the line.

Step 4: Streamlining Manufacturing in Custom Apparel Production

You have your designs, fabrics, and suppliers—now it’s time to fine-tune the actual manufacturing process. This step is as much about logistics as it is about production efficiency.

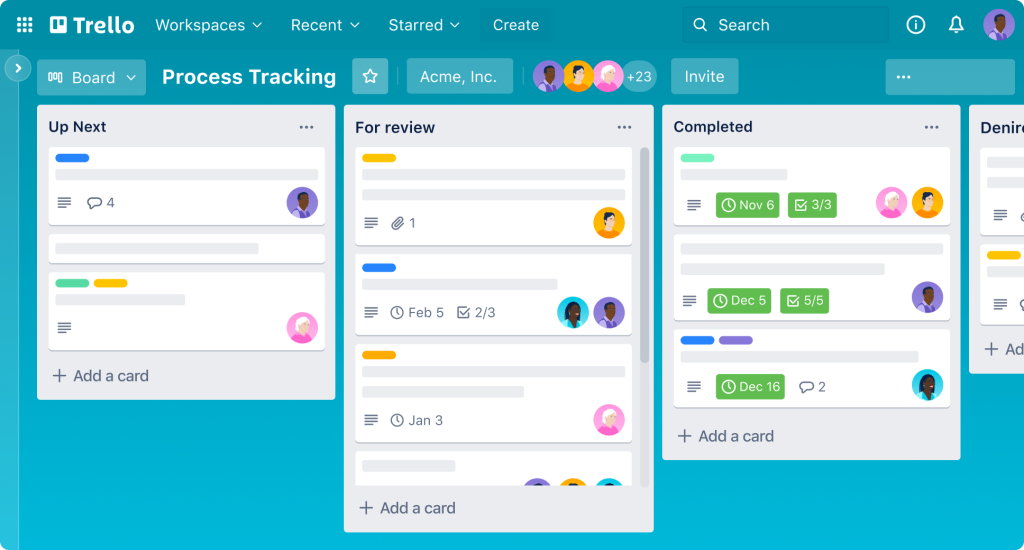

Trello, a project management tool, can be used to track your order timelines, manage tasks, and stay on top of communication between designers, suppliers, and shipping partners. Creating a clear workflow prevents mix-ups that can lead to missed deadlines or errors in the final garments.

Manufacturing itself can involve several methods: screen printing, embroidery, and digital methods like direct-to-garment (DTG). Digital printing is currently on the rise, growing at a 10% CAGR, with over 50 million custom garments produced annually by this method (rss.globenewswire.com). If you plan on scaling your teamwear brand quickly, careful selection of manufacturing techniques—like sublimation printing for high-quality, multi-color designs—can set you apart.

By planning your manufacturing stages meticulously and using tools like Printful Mockup Generator, you can streamline your entire custom apparel production cycle and minimize the headaches that often arise in the early stages of brand building.

Step 5: Marketing and Growth Strategies for Your Teamwear Brand

Getting your products made is only half the journey. You also need a marketing plan to reach potential customers and sustain your business growth. E-commerce sales of sports apparel are expected to grow by 9.2% annually (worldmetrics.org), so consider building your website or partnering with an online marketplace.

Tools such as social media ads and influencer marketing can help you reach large audiences quickly, especially if you showcase your unique designs or stress the sustainability aspect of your teamwear.

• Leverage Social Media: Platforms like Instagram and TikTok are effective spaces for highlighting bold designs or showcasing behind-the-scenes stories from your production process.

• Build Your Brand Story: Emphasizing your commitment to eco-friendly materials or charitable causes can resonate with modern consumers.

• Engage Local Teams: Sponsor local sports leagues or charitable events to get your uniforms in action and in front of potential new customers.

Once your initial line is launched, be ready to iterate based on customer feedback. Keep an eye on emerging trends, like athleisure styles that fit both athletic and casual wear needs. The women’s sports apparel market is growing by 7.5% from 2021 to 2028 (worldmetrics.org), which may present another niche.

Ultimately, scaling your brand requires consistent updates to your product line, building a recognizable brand identity, and maintaining strong relationships with suppliers to handle larger volumes.

Conclusion

Embarking on custom apparel production involves research, thoughtful design, reliable partnerships, efficient manufacturing, and a solid marketing strategy. By following these five essential steps—backed by careful planning and the right tools—you’ll be well on your way to building a successful teamwear brand that stands out.

Always keep the evolving trends in mind, like increased demand for sustainable materials and bold, personalized designs. And remember, custom apparel production is not a one-time project but an ongoing process that requires regular updates and improvements.

With the global sports apparel market projected to reach $248.1 billion by 2026 (worldmetrics.org), getting your teamwear brand established now can position you for long-term success. Good luck launching your vision, and may your uniforms shine brightly both on and off the field!